| « Bird Flu, and Did Viruses Suddenly Get Mad at Humans Starting in The Year 2019? | Pro-Vaxxer Trump IS Lining Up to Be The Vaccine "Colt Seavers" » |

Cleaning Your Vehicle's Throttle Plate is Easier Than You Thought

I like to cover a large range of topics, only most of the time, they tend to be rather political in nature. However, this one is not.

A little history first. I worked on cars for about 10 years before I went into a completely different industry. During that time I acquired all of my ASE certifications, except for Automatic Transmission. I missed the automatic transmission test by one question.🤣 No matter, at the time I worked for Toyota, and we didn’t rebuild transmissions, we replaced them with Toyota remanufactured units, so I wasn’t worried about internal bearing clearances, I didn’t deal with that.

My current vehicle is a 2008 Honda CR-V, recently, it began to exhibit a slightly erratic idle. So, I went straight to the source -- the throttle plate.

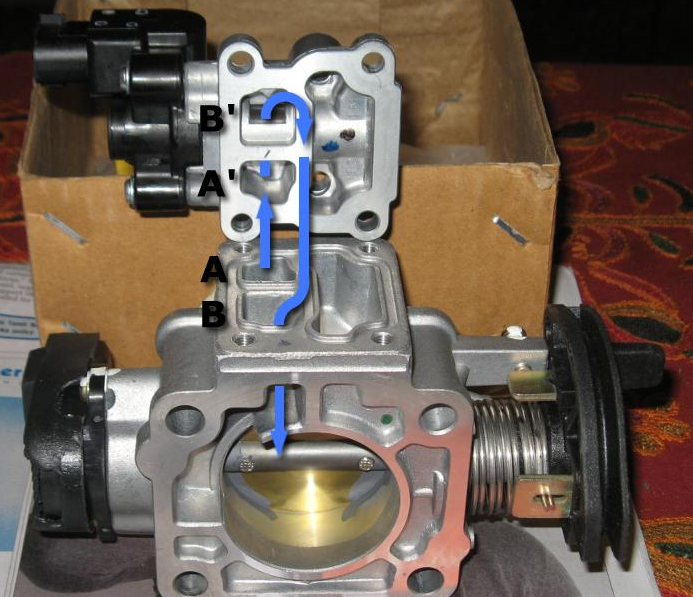

Throttle plates are a disk inside a tube, more or less, they consist of a butterfly valve assembly. As such, they never close completely, because they would stick if they did. Never closing all the way means there is a specific amount of leakage which is present past the throttle plate. Usually not enough to keep the engine running though. Additional air is required and provided by an air bypass assembly with a valve in-between. This is what controls the amount of intake air when the vehicle is at idle.

The 2008 Honda CR-V uses a fly-by-wire type throttle plate assembly (there is no physical connection between the throttle plate and the gas pedal). Toyota called this design ETCS-i (Electronic Throttle Control System [with] Intelligence or just Intelligent). Which, at the time, seemed kind of strange. They were replacing a $5 throttle cable, with an electronic servo assembly for throttle control. The reason for this was safety. The electronic throttle control could override the operator in the event that the vehicle lost traction, or during other maneuvers. That was the main driver for electronic throttle control.

With cars that still use a cable actuated throttle plate, it's easy to tell when the throttle plate needs to be cleaned. Most of the time the throttle will stick. You would go to give the car a little gas, and the pedal wouldn't go down, you'd have to mash a little harder then it would move. On cars with electronic throttle control, you never feel any sticking. There's no mechanical connection, and the servo motor is strong enough to move the plate without the driver ever noticing (it won't over-rev the engine).

There is a limit to the amount of air that can bypass the throttle plate, through the bypass assembly. Once the throttle assembly becomes dirty to the extent that the normally allowed leakage is below the amount needed to meet engine load, you'll start to notice it.

Let's say that the engine requires 100 CFM to idle with no load. 50 CFM comes from the throttle plate leakage, and 50 CFM comes from the air bypass. Then you turn on your air conditioner, now the engine might require 150 CFM. No worries because the air bypass assembly can provide up to 150 additional CFM. There's 50 CFM of headroom for the air bypass, this makes up for power steering or other small engine loads. The total with throttle plate leakage and air bypass is 200 CFM.

If the throttle plate becomes dirty to the point where it's passing close to zero CFM, you'll start to see the engine load exceed what the vehicle can adjust for. Then it becomes very noticeable. You'll feel the engine bog down at times.

The correction is simple, clean the throttle plate. There are many throttle plate cleaners on the market, but many of them use chemicals that can dissolve the coating on the aluminum parts of the throttle body. Knowing precisely which ones to use can be complicated.

I go to my old standby -- gasoline. The carbon that is deposited on the throttle body assembly and throttle plate is mostly carbon. Almost like soot in the chimney of a wood burning fireplace. Gasoline will dissolve it, and allow you to clean the throttle body assembly safely, without harming the coating on the aluminum parts.

Every time your cars engine is turned off. There is residual fuel that is left in the cylinders and is not burned. That fuel vaporizes and floats up the intake contacting all of those aluminum parts. Therefore the coating used on the throttle assembly, and the intake in general is gasoline resistant.

I use a little gasoline, and an old rag to clean the throttle body assembly and the throttle plate itself. You will need to carefully remove the intake boot, and prop open the throttle so you can get in and around it with the rag, and wipe the edges of the plate, and the sides of the assembly. I use something made of wood to do this. Wood is strong enough to hold the plate open, but won't scratch the sides. I just use the back of a wooden handled wire brush, or a wooden dowel. Just use something that won't break, so you don't spend an hour trying to get it out of the vehicle's intake!

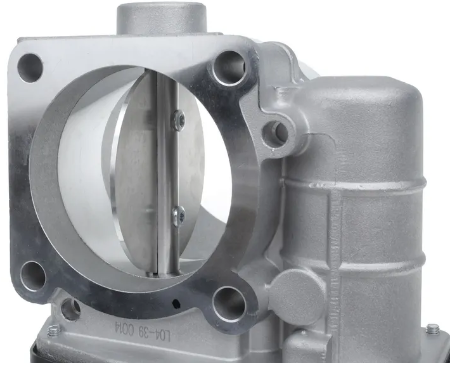

Here's what my throttle plate looked like before cleaning.

This is my throttle plate after cleaning. Notice you can see the gap around the edges more clearly now that the soot has been removed.

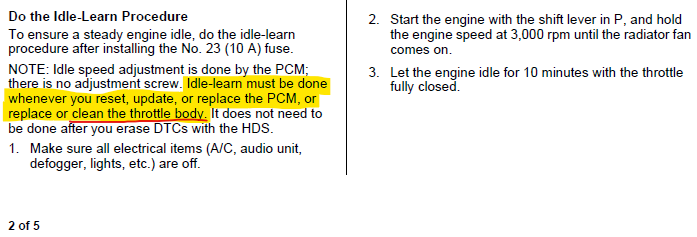

On most cars, simply cleaning the throttle plate is all that's needed. However, with my 2008 Honda CR-V there is an idle relearn procedure. If you have a different make of car, you'll have to scour the internet to see if there is an idle relearn procedure for your vehicle as well.

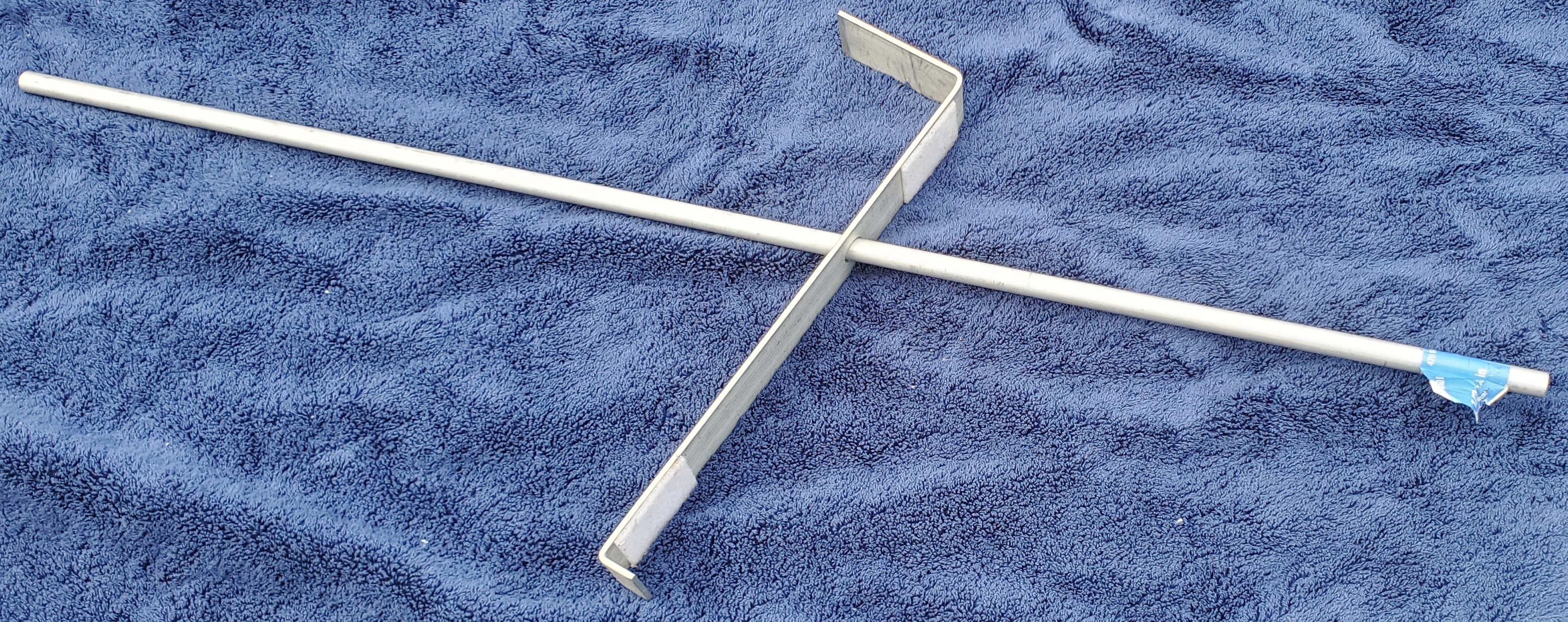

In order to run the engine at 3,000 RPM until the cooling fans come on, I used a pedal hold-down tool. We used to have these tools to lock the brakes on cars that were on an alignment rack. I remember because the tool from Hunter was around $120 back in the mid 1990s. But you can just make one out of scrap metal for free.

Here are both pieces of it apart. The aluminum slat piece was something I originally made to put Vinyl Plank Flooring together with, but I never used it. That's why there is fuzzy Velcro stuff on it. It worked nicely for this though.

When it's put together it looks like this.

Here's how it works in the car. As you can see, it presses against the seat, then against the gas pedal.

The rod binds on the slat with a hole in it. It's a super simple tool, but also super useful. You can also use it to hold the brake pedal down to check your own brake lights!

Hopefully this will help some people to get their car running right again.

What do you think?

Please leave a comment, like it or hate it... You DO NOT need to register to leave a comment. Email addresses are NOT used. Just make one up "someone@somehost.com"